Introduction To Swastik Synergy Engineering Pvt. Ltd. (SSEPL)

I. GENERAL INFORMATION

Swastik Synergy Engineering Pvt. Ltd. (SSEPL) is a leading manufacturer and supplier of fire protection equipment and systems in India. Founded and operating in Mumbai, SSEPL owns a modern manufacturing facility located in the Khopoli Industrial Area – a strategically convenient location for both domestic and international production and distribution.

With a skilled workforce, a large-scale factory, and a strict quality control process, SSEPL currently supplies a wide range of fire protection equipment, tools, and systems for various sectors such as high-rise buildings, industrial zones, hospitals, shopping centers, and especially the Swastik Synergy Kitchen Fire Suppression System – the first kitchen fire suppression solution in Asia to receive UL300 certification from UL Listed. This system is designed for industrial kitchens, which have a high risk of fire and explosion caused by grease and cooking equipment.

Some Outstanding Awards Achieved by SSEPL:

-

Marriott Global Design Asia Pacific Confluence 2018

Certificate of Appreciation for Swastik Synergy’s contribution at the annual conference organized by Hotelier India in collaboration with Marriott International, focusing on best practices, initiatives, and profitability in hospitality design. -

Intersec 2018, Dubai: Synergy Kitchen Fire Suppression System of the Year 2018

This award was presented at the Intersec 2018 Exhibition in Dubai, recognizing Swastik Synergy’s Kitchen Fire Suppression System as the Best Kitchen Fire Suppression System of the Year. Intersec is the world’s largest exhibition for security, safety, and fire protection, where products and systems are evaluated and honored for innovation and excellence.

II. INTRODUCTION TO THE SSEPL MANUFACTURING PLANT IN KHOPOLI

The Swastik Synergy manufacturing plant in Khopoli is a modern production facility fully equipped with advanced technology. Covering an area of several thousand square meters, the plant operates under a tightly controlled production process that adheres to international standards such as:

-

ISO 9001:2015 Quality Management System

-

Safety and performance certifications from organizations such as UL (Underwriters Laboratories)

-

Compliance with NFPA (National Fire Protection Association) standards from the United States

-

Conformance with local and international regulatory requirements

Production Process at the Swastik Synergy Factory

One of the key factors behind SSEPL’s success lies in its well-controlled and optimized manufacturing process. Every product produced by the company goes through the following stages:

1. Research and Development

The R&D team of SSEPL continuously researches and develops new technologies to enhance the efficiency and reliability of its fire protection systems. The company’s engineers regularly update their knowledge of the latest international standards and technological trends in the fire safety industry.

2. In-house Technical Design

Using modern CAD/CAM software, SSEPL’s design engineers create detailed drawings for each component of the system. Every design is optimized for functionality, durability, and aesthetics.

3. Metal and Material Fabrication

All system components are manufactured from high-quality materials such as stainless steel 304/316, copper, aluminum, and other special alloys. The fabrication process is carried out on modern CNC machines, ensuring high precision and consistent quality.

4. Assembly and Testing

After fabrication, the components are assembled into modules and complete systems. Each product undergoes a series of rigorous performance and safety tests before leaving the assembly line.

5. Quality Control

The QC (Quality Control) Department of SSEPL conducts 100% inspection of all products before shipment. Inspection criteria include:

-

Compliance with design specifications

-

Conformance with international safety and performance standards

-

High-quality finishing and craftsmanship

-

Complete documentation and labeling

6. Packaging and Transportation

After passing quality inspection, products are carefully packed in reinforced carton boxes or wooden crates, depending on transportation requirements. Each shipment is labeled and tracked through an advanced logistics management system.

Factory Operations Overview

As shown in the video, the SSEPL factory operates with a large, professional workforce ensuring a smooth production workflow — from in-house design, product assembly, and quality inspection to packaging and delivery. This ensures that every customer and business partner receives high-quality, safe, and reliable products.

In addition, SSEPL provides a wide range of products in the fire protection sector, including:

-

CO₂ Fire Suppression Systems

-

Gas-based Fire Suppression Systems

-

Portable Fire Extinguishers

-

System Components such as Heat Detection Tubes and Control Panels for the Con-Ferno-E Electric Kitchen Fire Suppression System and most notably, the company’s flagship product that has earned multiple international awards and global recognition — the Swastik Synergy Kitchen Fire Suppression System.

III. SWASTIK SYNERGY KITCHEN FIRE SUPPRESSION SYSTEM

The Synergy Kitchen Fire Suppression System is specifically designed for industrial kitchen environments, fully complying with international standards such as UL 300 and NFPA 17A. Using a non-toxic wet chemical agent, the system ensures human safety and environmental friendliness during operation. Its structural design provides comprehensive coverage of the entire protected area, ensuring interlocking protection and direct access to high-risk cooking equipment and surfaces prone to fire hazards.

The Synergy system supports two flexible activation modes: automatic and manual. Automatic activation is triggered through a fusible link or heat-sensing cable, while manual activation is performed via an emergency pull station located nearby. In the event of a fire, the system automatically activates audible and visual alarms and sends interlock signals to shut off the gas supply, electrical circuits, and exhaust fans, or to connect with the building’s main fire alarm system. All of these functions work together to ensure 24/7 continuous protection for the kitchen area, minimizing the risk of fire incidents and reducing potential damage to people and property.

LEARN MORE ABOUT THE SWASTIK SYNERGY KITCHEN FIRE SUPPRESSION SYSTEM HERE

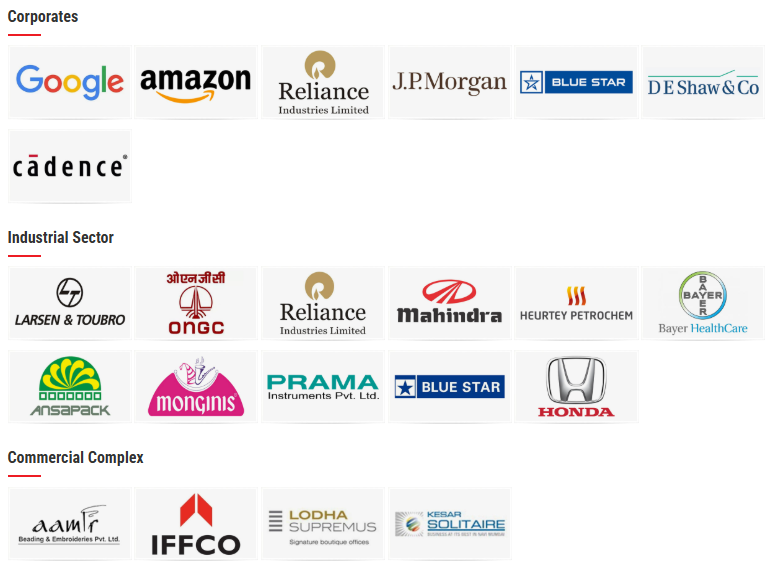

IV. FEATURED CLIENTS

SMARTTECH – PRESTIGIOUS UNIT PROVIDING SYNERGY KITCHEN FIRE SUPPRESSION SYSTEM IN VIETNAM

SmartTech is not only the official distributor of the Swastik Synergy kitchen fire protection system in Vietnam, we are also a partner to protect kitchen safety, so you can rest assured about the continuous operation of your business.

Phone (Zalo): 0981.909.051